Applications

Showing all 24 results

-

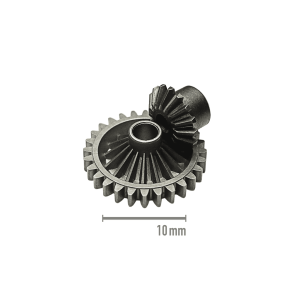

Gear

Bevel gear and Miter gear

Bevel gear : 8.78×8.78×5.75 mm. / Miter gear : 15x15x5.12 mm. These set of gear was traditionally manufactured by CNC machining, however, due to its minituarisation, it was necessary to change to μ-MIM® technology. Tolerance: Bevel gear : ≤ 0.5% / Miter gear : ± 0.007 mm

-

Exterior Component

Frame part (Eyewear)

It is possible to achieve a small titanium part without post-processing.

-

Exterior Component

Heat sink

In addition to components made of pure copper, we also fabricate components made of copper alloys (nickel-white, cupronickel) and composites of copper and diamond.

-

Exterior Component

Hinge part (Titanium part)

The eyewear is made of titanium alloy. Micro MIM technology is ideal for serial production of titanium material because it is one of the difficultto to cut. It is possible to achieve such a small titanium part without any postprocessing.

-

Holder

Holder for sensor

This holder for sensor has a very thin wall thickness of 0.08mm (80μm) on thinnest part, which is mass produced. Its tolerance is less than ±0.1%.

-

Pipe

Inside conductor

It is impossible to make a pure copper part in mass production because it is considered difficult to cut.Using our micro metal injection moulding process, we are able to mass-produce this copper part in serial production.

-

Gear

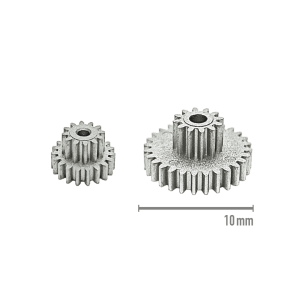

Integrated helical gear and spur gear

Integrated gear such as this helical and spur gear with the module of 0.025mm is mass produced with tolerance within 0.3%. Due to the small particle sized metal powder we use, you can hardly see the partling line on this component. By integrating two or more parts into one component, you can reduce the assembly process time and cost.

-

Gear

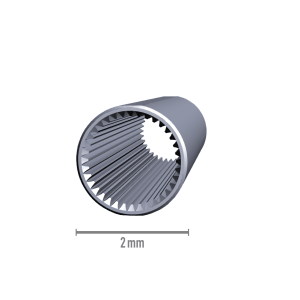

Internal gear

μ-MIM® small gear production can be achieved without a tool, thus stable high-quality micro gear serial production is achieved. It is more difficult to assure high quality with the smaller gear.Our original quality analysis system includes measurement XrayCT SEM and high-end optical measurement system.Importantly, Our original analysis software will be used to compare the measured data with the 3D drawing data to show the pitch error, tooth line etc.

-

Nozzle

Laval nozzle

The image of the cross section shows this laval nozzle with gradient diameter shape. It is difficult to manufacture by EDM, ECM, laser process or MIM.μ-MIM® can be used to make various shape nozzles.

-

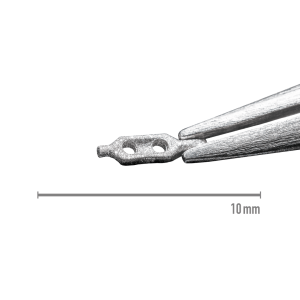

Forceps

Medical forceps (Disposable medical device)

When produced by machining, chucking is difficult and very costly.

-

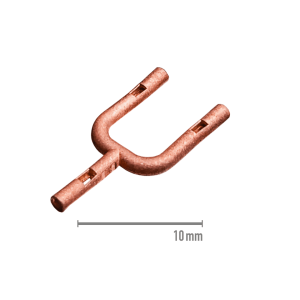

Pipe

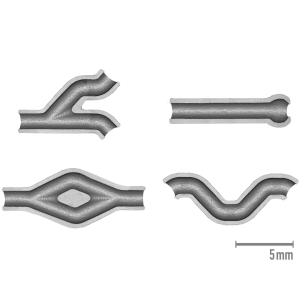

Medical Pipe

We are capable of mass producing micro pipe with very complex internal flow channel, which is difficult to produce with conventional manufacturing technology, such as machining. The internal shape can be measured by the x ray CT scan.

-

Gear

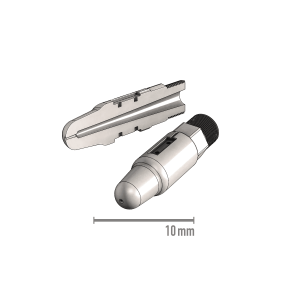

Micro internal helical gear

Normally, non-penetrating shape such as this internal helical gear with internal diameter of 10mm or smaller cannot be manufactured by CNC machining. μ-MIM® technology utilizes mould, which make such shapes to be produced for mass production. Even this helical gear with module 0.2 or less can be mass produced, which is very difficult with other manufacturing methods.

-

Nozzle

Micro Nozzle

0.03 mm is actually smaller than a standard hair diameter. It is said φ 0.05 mm is the smallest limit by machining at this moment. Our moulding and sintering technology using super fine metal powder, which cultivated as μ-MIM technology, realizes dense smooth surface, the roughness of Ra = 0.3 without post-processing. In microfabrication like this nozzle, it is difficult to achieve this surface quality even with the latest laser processing technology due to the problem of dross deposits or residual thermal stress and so on.

-

Nozzle

MIM Nipple

By utilizing our μ-MIM® technology, hollow structure on the MIM nipple component is realized. It is an example of down sizing of serial production parts for medical devices with difficult-to-machine material.

-

Pipe

MIM Nozzle

This OEM nozzle component has a hollow internal structure and requires sharp edges in the external design. Production of these nozzles requires tight tolerances of ±0.02 mm for the internal design. With our micro-MIM technology, we can support such production with short delivery times and can support customers with larger lot numbers.

-

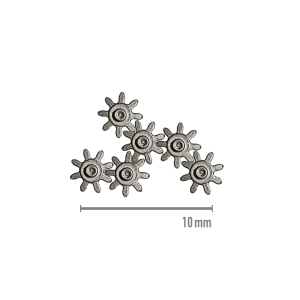

Gear

Multi step gear

Two step gears such as these components are produced for mass production with near net shape and stable high quality. Integrated gear with shaft are often produced by our μ-MIM® technology.

-

Gear

Pinion gear

The μ-MIM® technology enables stable, continuous production of small precision gears. We have good relationships with mould manufacturers, which enables us to achieve stable, continuous production of precision gears.Precision moulds lead to the stable production of gears with complex designs with low surface roughness, and µ-MIM® raw materials perfectly replicate precision mould designs.With a surface roughness Ra of 0.43 µm, additional polishing steps can be omitted.

-

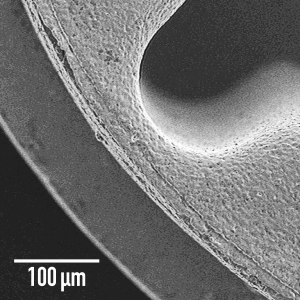

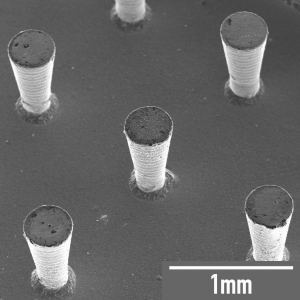

Shaft

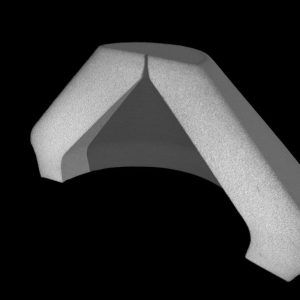

Reverse taper micro structure

The anchoring effect of the reverse taper micro pillars on the picture will strengthen bond strength physically.

-

Shaft

Shaft (Direct bonding technology)

This technology makes it possible to produce parts with more complex designs and combinations of different materials, which is not possible with one-shot moulding.The SEM image above shows the results of strength verification. It can be seen that the strength of the joint is sufficiently high, as there are no break points in the joint.

-

Nozzle

Small nozzle

These 17-4PH (SS630) nozzles are used in the semiconductor industry. Due to design and tolerance requirements, the CNC machining chuck had to be changed several times during the process, resulting in high component costs. The customer selected our MIM process for its productivity, tolerances and quality.

-

Cylinder

Special part for key cylinder

A component such as this special part for key cylinder is manufactured by our 3D-μ-MIM® technology, which is our original invention where a SP mould is created and dissolved/melted in the debinding process. This method enhances your component design freedom when you want to have hollow structure, undercut structure and so on.

-

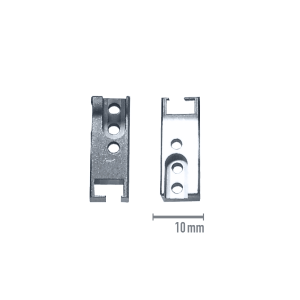

Holder

Tape holder

These parts are stainless steel components manufactured using micrometallic injection moulding technology, using fine stainless steel powder, mixed with a proprietary recipe manufactured in-house.The parts are characterised by a smoother surface roughness and higher density compared to those produced by conventional MIM processes.When manufactured by machining, costs are higher and lead times are longer.

-

Propeller

Titanium propeller

In this OEM part made of titanium material, we apply world-leading titanium powder with our binder and create a free-form design, tight tolerance, thin wall thickness without any post-processing or secondary processes. Titanium is one of the most difficult parts to make because of its mechanical properties, but we are able to make it with our micro metal injection moulds.

-

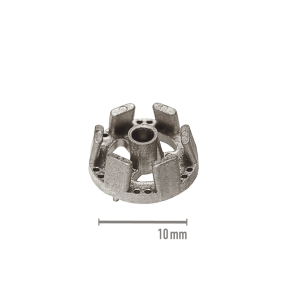

Yoke

Yoke part

Soft magnetic materials are among the most difficult materials to machine and are difficult to produce in series.μ-MIM® has a proven track record in the continuous production of small, complex designed soft magnetic material components with good magnetic properties and satisfying tight tolerances.Unlike conventional powder metallurgy, it achieves a density of 98% of that of wrought materials and satisfactory magnetic properties.