Nozzle

Showing all 5 results

-

Holder

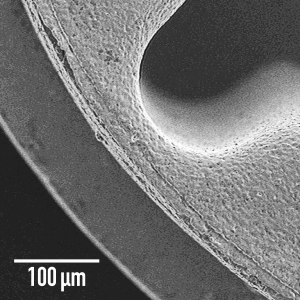

Holder for sensor

This holder for sensor has a very thin wall thickness of 0.08mm (80μm) on thinnest part, which is mass produced. Its tolerance is less than ±0.1%.

-

Nozzle

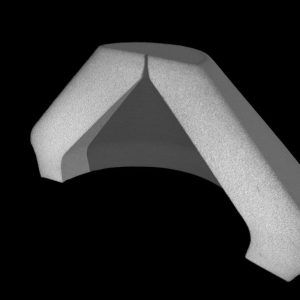

Laval nozzle

The image of the cross section shows this laval nozzle with gradient diameter shape. It is difficult to manufacture by EDM, ECM, laser process or MIM.μ-MIM® can be used to make various shape nozzles.

-

Nozzle

Micro Nozzle

0.03 mm is actually smaller than a standard hair diameter. It is said φ 0.05 mm is the smallest limit by machining at this moment. Our moulding and sintering technology using super fine metal powder, which cultivated as μ-MIM technology, realizes dense smooth surface, the roughness of Ra = 0.3 without post-processing. In microfabrication like this nozzle, it is difficult to achieve this surface quality even with the latest laser processing technology due to the problem of dross deposits or residual thermal stress and so on.

-

Nozzle

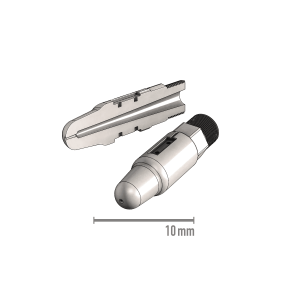

MIM Nipple

By utilizing our μ-MIM® technology, hollow structure on the MIM nipple component is realized. It is an example of down sizing of serial production parts for medical devices with difficult-to-machine material.

-

Nozzle

Small nozzle

These 17-4PH (SS630) nozzles are used in the semiconductor industry. Due to design and tolerance requirements, the CNC machining chuck had to be changed several times during the process, resulting in high component costs. The customer selected our MIM process for its productivity, tolerances and quality.