| Micro MIM News

We will be exhibiting at MD&M Midwest in Minneapolis from October 21 to 22, 2025

We will be exhibiting at the MD&M Midwest 2025 to be held at the Minneapolis Convention Center, USA from October 21 to 22, 2025.

Read More | MIM Tips for Designers

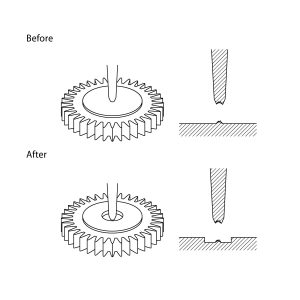

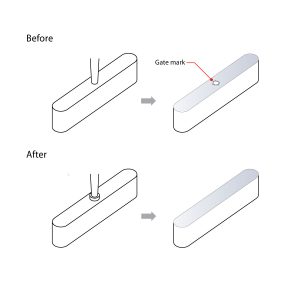

Manufacturing / Gate treatment Pt. 3

Unfortunately, it is impossible to avoid the rough surface at the gate. Normally, the gate roughness is convex, thus post treatment might be required.

Read More | MIM Tips for Designers

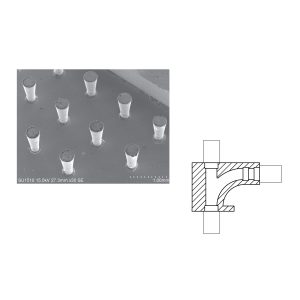

Manufacturing / Undercut and internal curve design

Applying our 3D-MIM technology, it is possible to mass produce complex hollow design or micro size configuration.

Read More | MIM Tips for Designers

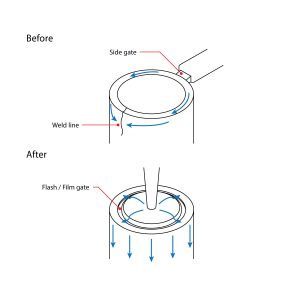

Manufacturing / Gate treatment Pt. 2

Employing film or flash gate to eliminate weld line and improve the roundness tolerance.

Read More | MIM Tips for Designers

Manufacturing / Gate treatment Pt. 1

Apply higher level of gate will minimize the polishing amount.

Read More | MIM Tips for Designers

Manufacturing / Hook

Unfortunately, it is impossible to avoid the rough surface at the gate. Normally, the gate roughness is convex, thus post treatment might be required.

Read More | MIM Tips for Designers

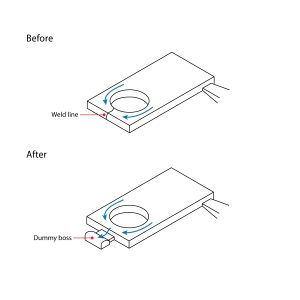

Manufacturing / Hole

Apply dummy boss in front of the feedstock confluence point to minimize the weld line defects.

Read More | MIM Tips for Designers

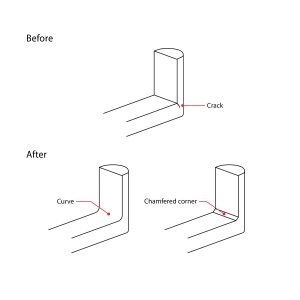

Manufacturing / Corner

Apply curve or chamfered corner to avoid demoulding or inhomogeneous problems.

Read More | MIM Tips for Designers

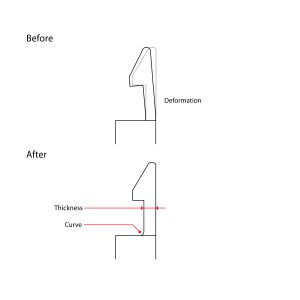

Manufacturing / Thickness Pt. 2

Either eliminating the sudden huge thickness change or giving curve at the corner will minimize the problems above mentioned.

Read More | MIM Tips for Designers

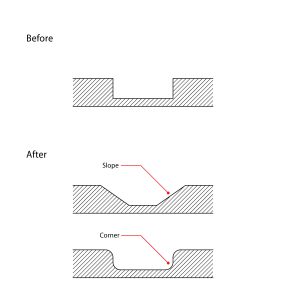

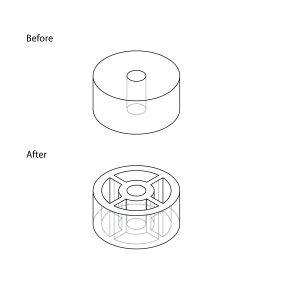

Manufacturing / Thickness Pt. 1

If the thick design is necessary, hollow out from the possible side. These hollows will help to avoid the sink mark or void. Also it helps minimize the unit price.

Read More